RTCA/DO-160 is the globally recognized standard for testing airborne equipment under real-world environmental conditions. It sets the benchmark for evaluating performance against factors like temperature extremes, vibration, shock, humidity, and electromagnetic interference.

This standard applies to a wide range of aviation equipment and aligns with EUROCAE Minimum Operational Performance Specifications (MOPS), RTCA Minimum Performance Standards (MPS), and manufacturer-specific equipment specifications. Compliance with DO-160 ensures reliability and confidence in equipment performance during actual operations.

DO-160 is a crucial step in ensuring safety, reliability, and performance of airborne equipment in real-world operational environments. Failure to comply can result in:

By partnering with Aversan, you can achieve DO-160 certification with confidence, knowing your systems meet the highest industry standards and are prepared to perform under the most demanding conditions.

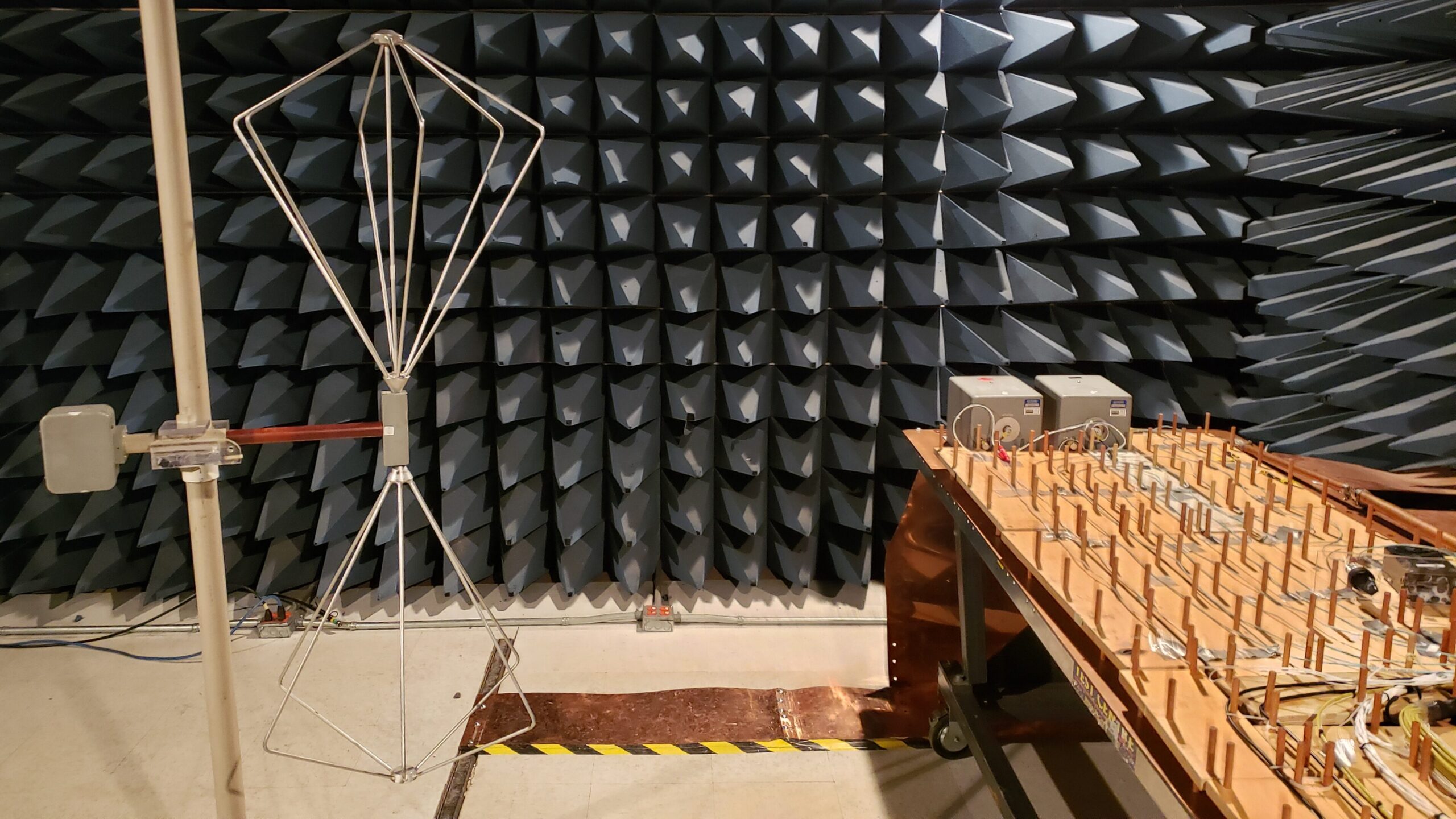

Aversan is a leading provider of DO-160 testing, offering accredited facilities equipped with state-of-the-art technology. Our team of experienced engineers and technicians ensures precision and reliability in every test, helping you meet compliance requirements with confidence.

We go beyond standard testing to offer comprehensive support throughout your DO-160 compliance process. From early-stage design guidance to post-test analysis, we ensure your equipment meets the highest industry standards.

|

DO-160 Testing Services by Aversan | |

|---|---|

|

Section 4.0 – Temperature and Altitude | |

|

Section 5.0 – Temperature Variation | |

|

Section 6.0 – Humidity | |

|

Section 7.0 – Operational Shocks and Crash Safety | |

|

Section 8.0 – Vibration | |

|

Section 9.0 – Explosive Atmosphere | |

|

Section 10.0 – Waterproofness | |

|

Section 11.0 – Fluids Susceptibility | |

|

Section 12.0 – Sand and Dust | |

|

Section 13.0 – Fungus Resistance | |

|

Section 14.0 – Salt Fog | |

|

Section 15.0 – Magnetic Effect | |

|

Section 16.0 – Power Input | |

|

Section 17.0 – Voltage Spike | |

|

Section 18.0 – Audio Frequency Conducted Susceptibility – Power Inputs | |

|

Section 19.0 – Induced Signal Susceptibility | |

|

Section 20.0 – Radio Frequency Susceptibility (Radiated and Conducted) | |

|

Section 21.0 – Emission of Radio Frequency Energy | |

|

Section 22.0 – Lightning Induced Transient Susceptibility | |

|

Section 23.0 – Lightning Direct Effects | |

|

Section 24.0 – Icing | |

|

Section 25.0 – Electrostatic Discharge | |

|

Section 26.0 – Fire and Flammability |

Explore three Aversan projects meeting strict aerospace certification standards.

"*" indicates required fields