How to position your product for success with Model Based Systems Engineering?

In the globalized and fiercely competitive world of today, it’s critical for engineering companies to exhibit smart and integrated product development capabilities that are aligned with latest technological advancements and changing customer needs. The competition is not only about building intelligent products but also about creating a more personalized experience for customers. It’s exciting yet challenging to make a component or sub-component of a system work seamlessly with other components of the system, especially when different parts of the system are developed in separate geographical locations.

To manage increasing complexities, companies need smart systems engineering practices to stay at the forefront of changing technology and customer needs.

Most companies find it hard to optimize competing forces in the development process such as cost, quality, reliability, dependability, time to market etc. to provide finest solutions. These forces can at times be contradictory such as quality and cost parameters; companies cannot excel in both. Although different management approaches have been introduced to control projects and maintain a balanced equilibrium between critical forces, nothing has worked out better than Model Based Systems Engineering.

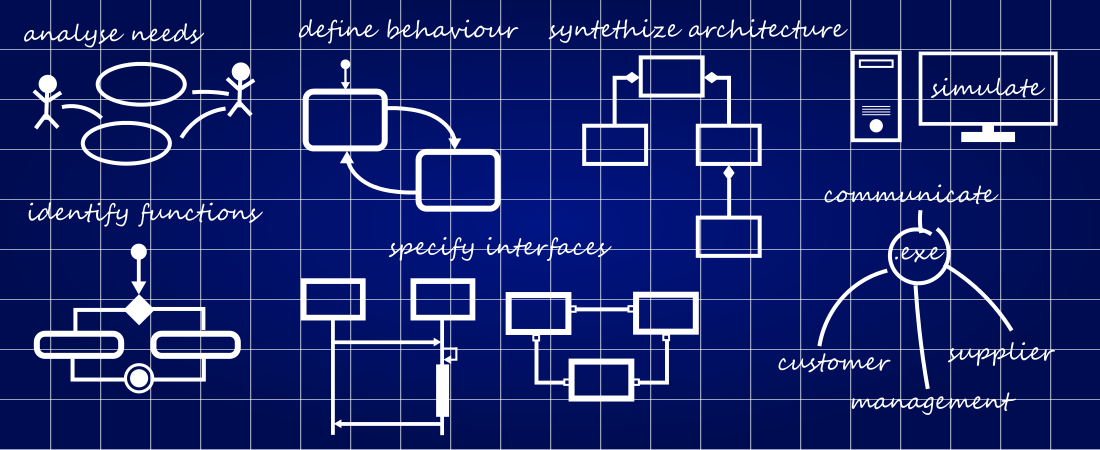

Model Based Systems Engineering (MBSE) is a transition from traditional code-centric methodology to a smart model-driven approach that uses models to define the system and visualize interdependencies. MBSE reduces the risk of errors, especially when introducing changes, improves quality and accommodates system implementation and testing when not all components of a system are readily available or implemented yet.

Let’s dive straight in.

Introducing Model Based Systems Engineering for product and project development

Model-Based Systems Engineering or MBSE is the practice of developing a set of related system models that help define, design and document a system under development. It is the formalized application of modelling requirements, design, analysis, and verification activities as a cost-effective way to explore and document system characteristics. By testing and validating system characteristics early, models facilitate timely learning of properties and behaviours, enabling fast feedback on requirements and design decisions.

MBSE was initially accepted and implemented by highly regulated industries to provide customized solutions and gradually gained recognition by others. The idea is to create a system domain model and use that model as a primary representation of behavior and dynamic performance of the system to be built. The implementation of MBSE procedures require all stakeholders to align their design to project needs based on the guidelines of the domain model. In such a scenario, model becomes the primary source of exchanging information for system engineers.

Some advantages of Model based systems engineering include:

- Improved alignment with products, which results in desired outcomes and a smooth line of communication throughout

- Improved quality and increased productivity of the design team

- Model based systems engineering fosters a deeper exploration of the design trade space

- Enhanced evaluation of solutions implemented against other project trade offs

- End product is much better aligned with requirements from different stakeholders and addresses customer needs appropriately.

- Facilitate Systems testing when all components or sub components under test are not readily available at the same location.

Here’s a case study demonstrating benefits of Model based system engineering for Avionics Systems.

The advantages are such that most engineering companies are now introducing advanced model based system engineering to make this optimization process part of the company’s core product development process that facilitates seamless project integration while addressing market and customer needs.

Here’s what Dr. Bruce Cameron has to say about MBSE in his introduction to the course at MIT.

Validation and Testing in Model Based Systems Engineering

One of the most important considerations during the validation and testing phase is developing a good set of cases for testing. During this stage, the team is required to consider multiple possibilities and think of the product from different perspectives, unlike considering it only from a system’s failure point of view where we can safely say whether or not the equipment passed the functional ability it was originally designed for. When utilizing MBSE, the domain model must be supportive of the entire SDLC, especially the verification and validation process so that data provided can be used towards further improving and refining the models for future use.

Model Based Systems Engineering for system testing is a powerful tool for helping engineers to maximize quality and efficiency in systems engineering as it incorporates verification and validation into each stage of the System Development Life Cycle (SDLC).

The standard MBSE procedures consider a wide array of factors that go above and beyond market studies and conceptual possibilities. For example, developing test cases involves multiple users and key stakeholders such as maintenance and operation divisions and most importantly, it takes into consideration the end user experience.

Our Approach

Even though MBSE can help companies reduce cost of testing and develop better quality products that address customer needs with reduced time to market, different engineering companies can look at MBSE in different ways based on their areas of expertise.

Aversan specializes in the design and development of mission and safety-critical avionics & test equipment, offering turn-key product development engineering services to our customers.Whenever possible, Aversan applies Model Based Systems Engineering approach for developing our products within aerospace, defense and rail verticals.

Aversan has built multiple Controls Integration and Verification test facilities for its clients over the past decade in order to integrate and verify systems engineering specification controls requirements in an automated fashion where the controls components were simulated using real-time dynamic models. This capability saves us significant hours in the development process by allowing engineering teams simulate their use cases instead of physically integrating and testing every single component of the product under development.

In our next blog, we will discuss the benefits of model based and automated system testing facilities.

If you’d like to explore how Aversan can help accelerate your product roadmap, reduce time-to-market and optimize the development and testing process for increased quality and efficiency, get in touch with us!